Complete mechanical and piping project management covering engineering, pre-commissioning, progress monitoring, and QA/QC controls with comprehensive welding and NDT tracking.

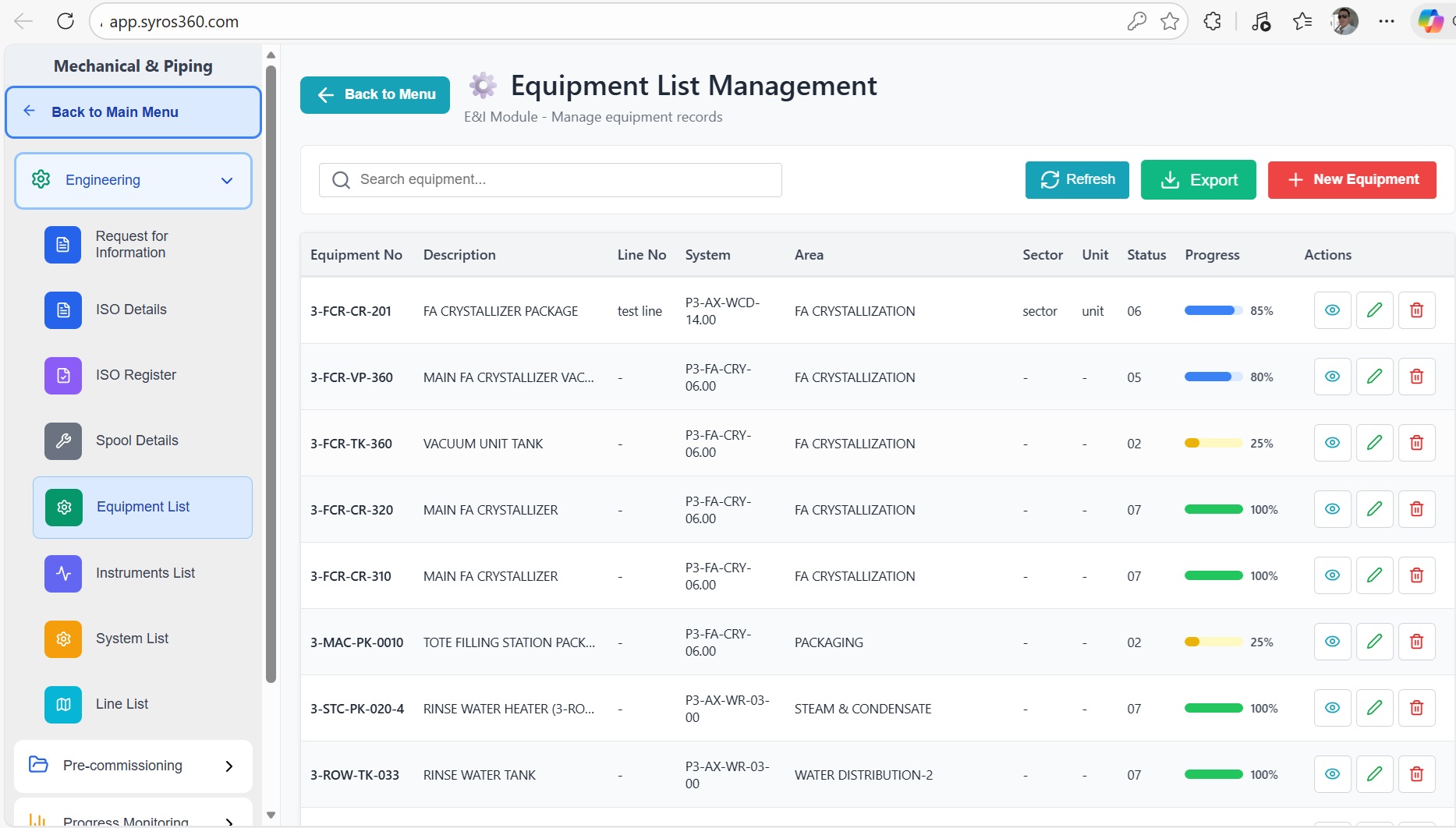

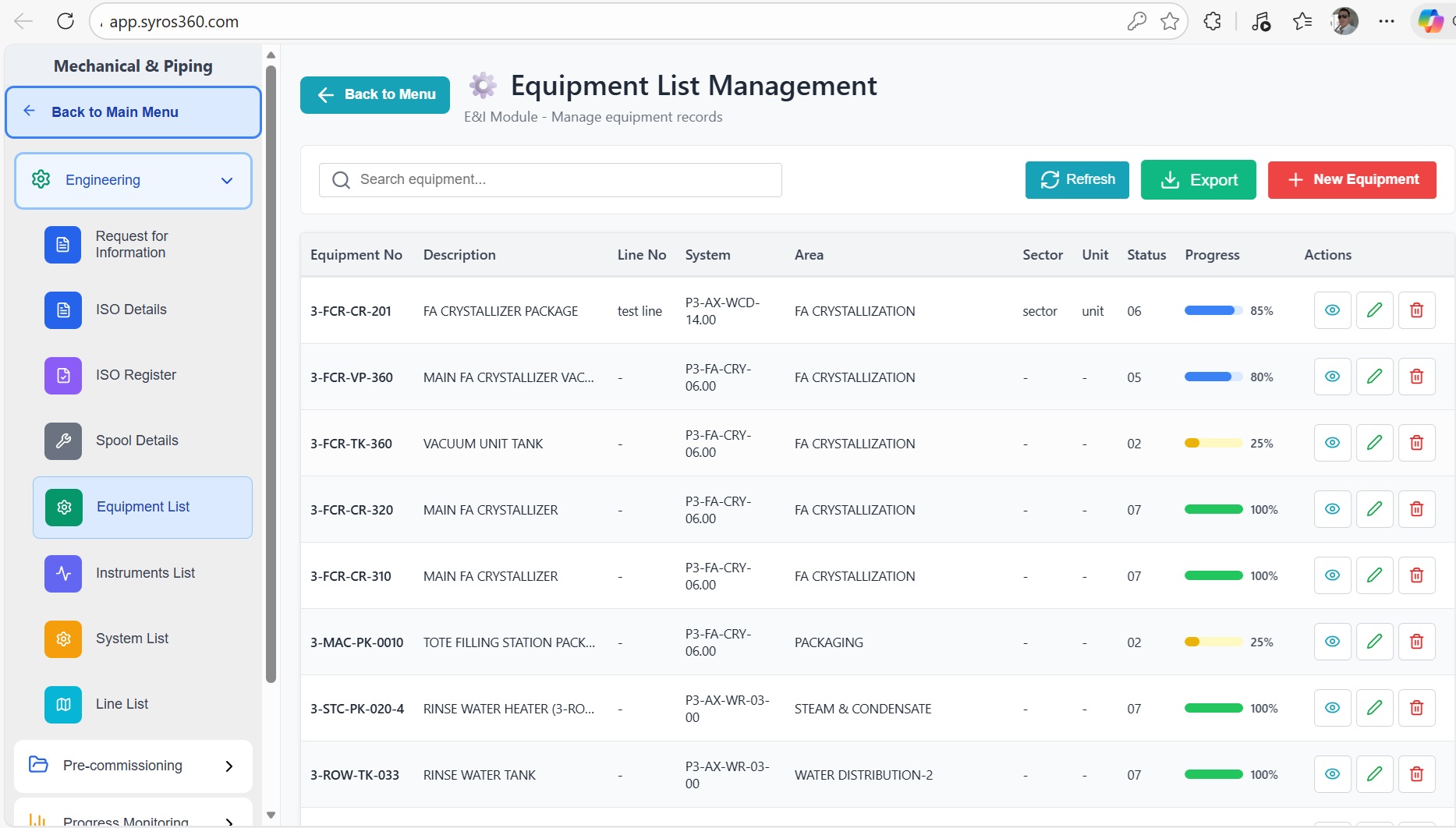

The system provides structured management of RFIs, ISO documentation, spool and equipment details, instrument and system registers, and comprehensive line list control.

It ensures organized oversight of punch lists, systematic tracking of inspection requests, and complete documentation of test packs to support project readiness.

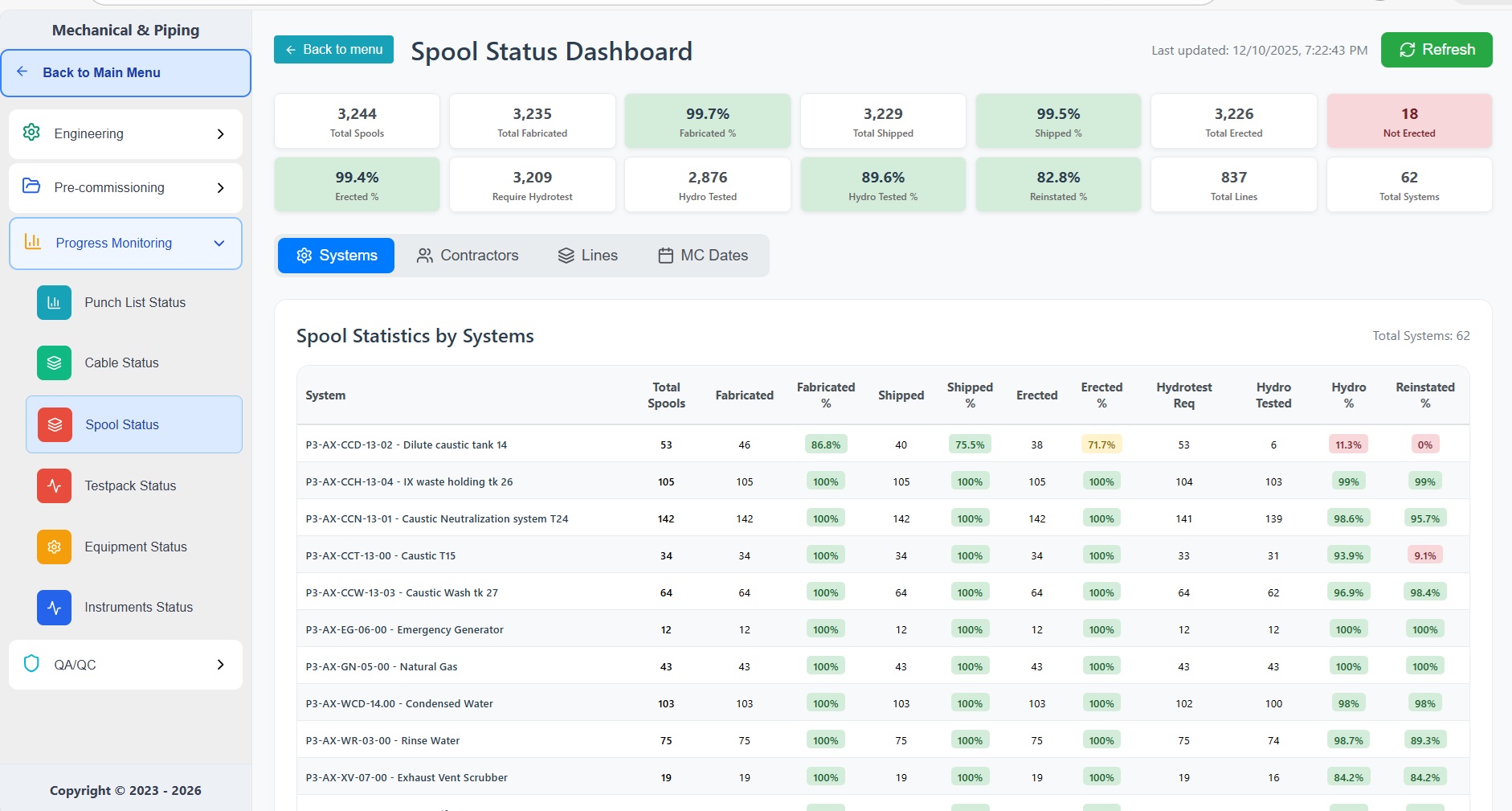

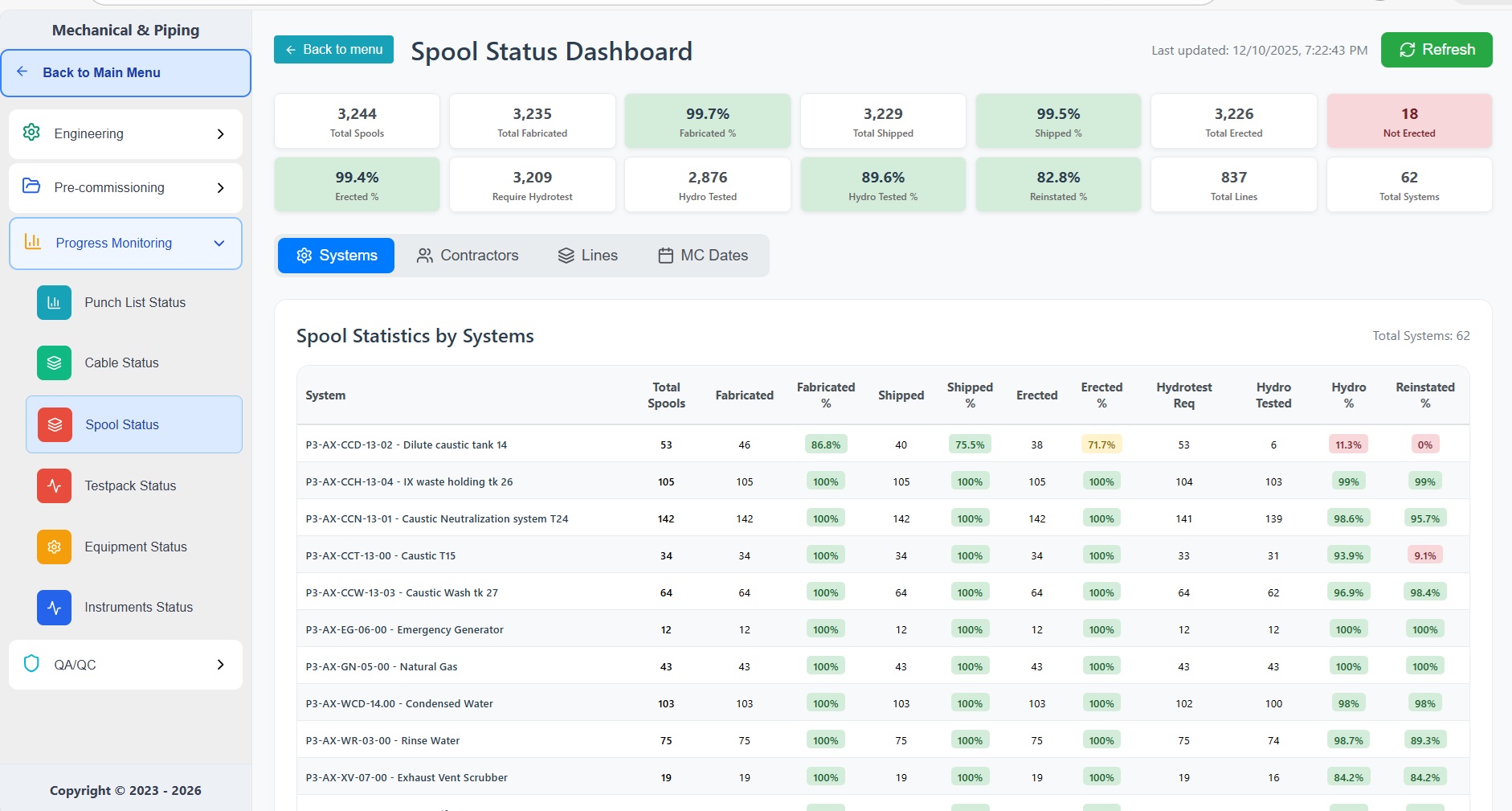

The platform enables real-time monitoring of progress indicators, including punch lists, cables, spools, test packs, equipment, and instrumentation statuses.

The module supports end-to-end QA/QC administration through centralized welder data, welding procedures, NDT requirements, weld mapping, NDT oversight, and daily welding reports.

Complete tracking of isometric drawings from creation to approval and implementation.

Detailed spool status tracking including fabrication, testing, and installation progress.

Comprehensive non-destructive testing tracking and reporting with detailed analysis.

Detailed welder performance analysis including repair rates and productivity metrics.

Comprehensive dashboards with full Power BI integration for advanced analytics and reporting.

Automated generation of daily welding summaries, NDT results, and progress reports.